Wiring

Car wiring is one of most builders least favourite stages as it's a mass of complicated same coloured wires all operating different components. Becuase of this we're going to tackle it over a few evenings as we don't want to be pulling our hair out over the build just yet.

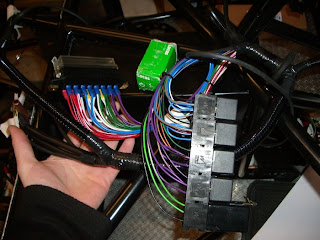

We need to wire all the lights, switches, sensor units, clocks and then meet the engine loom. This is how it looks positioned and labeled. If you're wondering what that massive copper tube is sticking out, that's the fuel return that we haven't cut and p-clipped in position yet.

To secure the wires into place we're using rivets and p-clips but we're waiting on some larger 12mm p-clips as we just have 10mm ones at the moment.

Pedal Box

Next in is the pedal box. We have a slight concern with this as the diagonal on the bulkhead gets in the way of the accelerator pedal. Marc has assured us that it won't need to be pushed back that far but we're going to file it down to allow it to be fitted centrally. I haven't got a before shot but it was completly rounded and we've added that "v" looking section.

We're going to paint the exposed metal once were happy that everything's in place. Moving on, we marked holes where we were going to put the cylinders and bolts through the bulk head. We also marked 4 points to attach the pedals to the floor. With a 38mm hole cutter we made the brake cylinder's holes, for the bolts we used an 8mm drill bit. We then attached the m8(12.9) bolts with two washers and a non-nylocked nut. This is so we can take the box out if we need to for the clutch and accelerator cables. The bias bar (a component giving more braking force to either front or the rear brakes depending on adjustment) was fiddley to get in and isn't in the right place but will do for the mock up. This is how it now looks screwed into the brake cylinder push rods.

On the engine bay side the brake cylinders are in place with the m8 bolts, washers and nuts ready to be linked up with the front and rear brake pipes.

With some baby p clips delivered in under 24 hours from Car Builder Solutions(frankly amazing considering it came via royal mail) we were able to complete the brake pipes.

We checked everything alligned properly and that spacing was under 6 inches. Then we attached the pipes with rivets and p-clips and it now looks like this.

Scuttle panel

Like the bulk head panels we cut and shaped the big piece of aluminium to make a scuttle panel with the chassis number on. We clamped it in place, centre punched points evenly around the edge of the panel then drilled holes through the ally and chassis using a 5mm drill bit.